Emerging Battery Technologies for Electric Vehicles

Adapting to the Next Wave of EV Battery Innovation

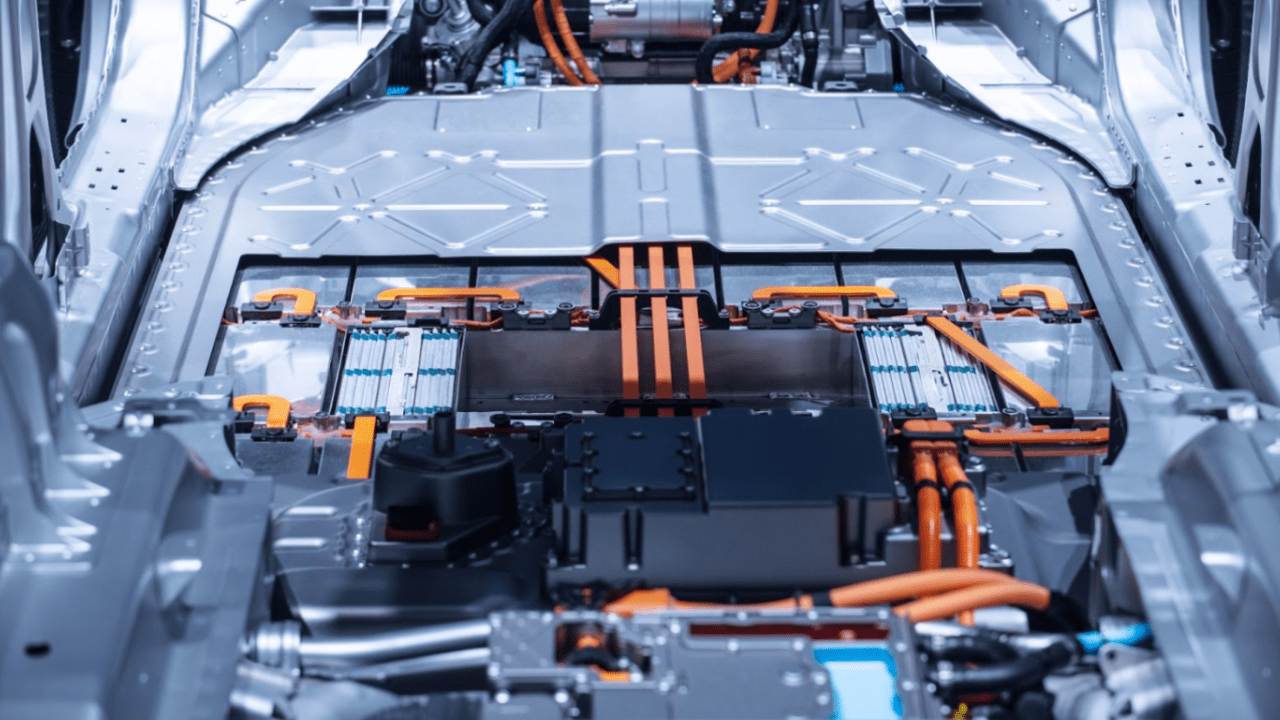

The landscape of battery technologies for electric vehicles (EVs) is set to experience transformative advancements. The rising need for clean energy and the growing popularity of EVs create significant opportunities for emerging battery technologies. As we advance toward more sophisticated energy solutions, these innovations are expected to offer greater efficiency, sustainability, and support for cutting-edge technologies. This article explores the advances in EV battery technology.

What’s on the Horizon for Electric Vehicle Batteries?

One major focus in battery development is enhancing energy density. Batteries with higher energy density can store greater amounts of power in a smaller size, which is particularly advantageous for both electric vehicles and portable devices.

Lithium-ion batteries, particularly those using nickel-cobalt-aluminum (NCA) or nickel-manganese-cobalt (NMC) chemistries, are favored for their superior energy density. Research is also exploring alternative materials, such as lithium-sulfur and solid-state electrolytes to further enhance energy storage capabilities.

Another promising area is the development of fast-charging batteries. Efficient recharging is essential for the broad adoption of EVs. Innovations in this field include improved electrode designs and the application of nanomaterials to increase surface area. Researchers are also working on optimizing charging methods, reducing heat, and integrating advanced cooling systems to enhance the efficiency of fast-charging battery technologies.

EV Battery Innovation: A Closer Look

Some promising developments expected to shape the future of EV battery performance include:

- Solid-state batteries: A revolutionary energy storage technology, poised to disrupt the status quo. Unlike traditional lithium-ion batteries that rely on a liquid electrolyte, solid-state batteries employ a solid electrolyte, offering a host of potential advantages. However, the transition to solid electrolytes presents significant challenges, such as interfacial resistance and mechanical stability.

Overcoming these hurdles could unlock a new era of energy storage, characterized by higher energy densities, improved safety, and faster charging times. Researchers are actively exploring innovative materials and manufacturing techniques to realize the full potential of solid-state batteries, paving the way for a more sustainable and electrified future.

- Lithium-sulfur batteries: These are a promising alternative to traditional lithium-ion batteries. They could offer higher energy density and reduced costs, thanks to the widespread availability of sulfur. While these batteries have the potential to significantly improve range and battery performance, challenges such as corrosion, sulfur’s conductivity, and overall battery longevity need to be overcome. New designs are being developed, which could solve the drawbacks.

- Advanced lithium-ion technologies: Ongoing innovations in lithium-ion batteries are expected to enhance energy density, charge times, and lifespan. New chemistries and improvements in electrode materials, such as high-nickel cathodes and silicon anodes, are driving these advancements. These upgrades aim to boost the efficiency and affordability of current lithium-ion batteries.

- Fast-charging technologies: Speeding up the charging process is crucial for widespread EV adoption. Advances in fast-charging technologies are focusing on improving electrode materials and optimizing charging protocols to reduce charging times significantly. Enhanced cooling systems and novel electrolyte formulations are also contributing to faster and more efficient charging solutions.

- Recyclable and sustainable batteries: As sustainability becomes a major concern, the development of recyclable and environmentally friendly battery technologies is gaining momentum. Innovations in battery recycling processes and the use of sustainable materials aim to minimize environmental impact and promote a circular economy in the EV battery industry.

- Dual-ion and sodium-ion batteries: Emerging alternatives such as dual-ion and sodium-ion batteries are being explored for their potential to offer lower costs and improved performance. Sodium-ion batteries, in particular, could provide a more sustainable and cost-effective option compared to lithium-ion batteries, given the abundance of sodium.

EV Battery Innovation and Wire-Harness Design

Advancements in battery technologies for electric vehicles (EVs) will bring several changes to wire-harness design. Here’s a look at how these developments might affect wire-harness requirements and design:

1. Higher Power and Energy Requirements

As batteries become more energy-dense and charging speeds increase, wire harnesses will need to manage higher power levels. This may require upgrading wire gauges and insulation to handle greater currents safely and effectively.

2. Enhanced Thermal Management

New battery technologies, especially those with rapid charging capabilities or higher energy densities, are likely to generate additional heat. Wire harnesses will need improved thermal management solutions to avoid overheating and maintain reliability. This could involve using materials that resist heat better and incorporating features to enhance ventilation or cooling.

3. Space Optimization

As battery packs become more compact and integrated, engineers must optimize wire harness designs to fit these new configurations. Advances in battery technologies might lead to more complex battery layouts, requiring more intricate and space-efficient wire routing. Designers wll need to develop more flexible and compact harnesses to adapt to these changes.

4. Durability and Longevity

With the introduction of new battery chemistries and designs, wire harnesses will need to be more durable to withstand the conditions associated with these innovations. This could include improved resistance to chemical exposure, vibration, and mechanical stress. To ensure long-term reliability, engineers may need to use enhanced insulation and robust connectors.

5. Connectivity and Integration

Advanced EV battery technologies may come with new control and monitoring systems that require additional sensors and communication lines. Wire harnesses will need to integrate these new components seamlessly, ensuring that all connections are secure and that data transmission remains accurate and reliable.

6. Weight Reduction

As EV battery innovation evolves, there may be opportunities to reduce the weight of wire harnesses through the use of lighter materials and more efficient designs. Reducing harness weight can contribute to overall vehicle efficiency and performance, complementing the benefits of advanced batteries.

7. Modularity and Flexibility

The rapid evolution of battery technologies may require wire harness designs to be more modular and adaptable. Harnesses that can be easily reconfigured or updated to accommodate new battery systems will be advantageous, allowing for more flexible manufacturing and maintenance processes.

8. Safety Considerations

Enhanced safety features will be crucial as new battery technologies are integrated into EVs. Wire harnesses will need to incorporate advanced safety measures, such as improved insulation, robust connectors, and fail-safes to handle the increased risks associated with high-power and high-energy systems.

9. Protection from EMI and RFI

With the advancements in battery technologies and the addition of new electronic components, managing electromagnetic interference (EMI) and radio-frequency interference (RFI) will become crucial. Wire harnesses will need to incorporate shielding and other techniques to minimize interference that could affect the performance of sensitive electronics and communication systems in EVs. This will ensure reliable operation and prevent potential disruptions in the vehicle’s electronic systems.

10. Green Wire-Harness Design

As battery technologies advance, wire harnesses must also embrace “green wire-harness design” to support sustainability goals. This approach focuses on reducing your environmental impact by using eco-friendly materials and optimizing production processes. Key strategies include employing recyclable or biodegradable materials, minimizing the amount of wiring used, and designing harnesses that conserve resources. Green wire harness design also prioritizes reducing waste and lowering energy consumption during manufacturing and throughout the harness’s life cycle. By integrating these practices, wire harnesses can effectively support new battery technologies while promoting a more sustainable and environmentally responsible automotive industry.

It’s worth noting that sustainable battery manufacturing is also gaining traction. The aim here is to minimize the environmental footprint of the manufacturing process. Manufacturers are implementing a variety of strategies for eco-friendly battery production, including the use of renewable energy sources, waste reduction, and responsible sourcing of materials.

Ask us for a free demo

As wiring harnesses grow in complexity, you need to streamline your design and manufacturing processes. Best-in-class, cloud-based Arcadia software gives you the advanced tools you need for every step. To show you how you can improve your efficiency and productivity, we’re happy to give you a free demonstration. If you have any questions, we’re here to help.