11 Vital Questions To Ask While Evaluating CAD Platforms For Manufacturing

Deciding on a software or platform to bring onto your company is crucial; you’re making a decision that impacts your day-to-day workflow, likely for years to come. You want to make the right decision for your specific needs and team. We’re here to help. We’ve assembled a list of questions to ask when evaluating CAD platforms for manufacturing harnesses, be it our platform, Arcadia, or other solutions. If you’re searching for a new platform or bringing one on for the first time, we recommend asking the following during your evaluation process.

1 – What can I expect from the user interface?

This question is self-explanatory but meaningful, any tool you bring on must work for your team. It’s crucial to understand how intuitive the user interface is or isn’t and how easily you can navigate the platform. We recommend asking for a demonstration of each platform you’re looking at or test-driving it during a trial.

2 – How easily can I use this solution with my team members or third parties if necessary?

Aside from how intuitive the solution is for you, understand how it fits into your team’s workflow. Depending on your company, you’ll want to know if the software has capabilities allowing for easy collaboration and data management across your team/locations.

3 – How does the software handle version control and design revisions?

Accurately controlling access to your designs and keeping a record of multiple design versions is another key aspect to consider. Your team likely needs to restrict access to certain projects or features based on the user permissions and groups, ensuring only designated members make edits. Additionally, keeping records of revisions makes it easy to go back and adjust designs should the need arise.

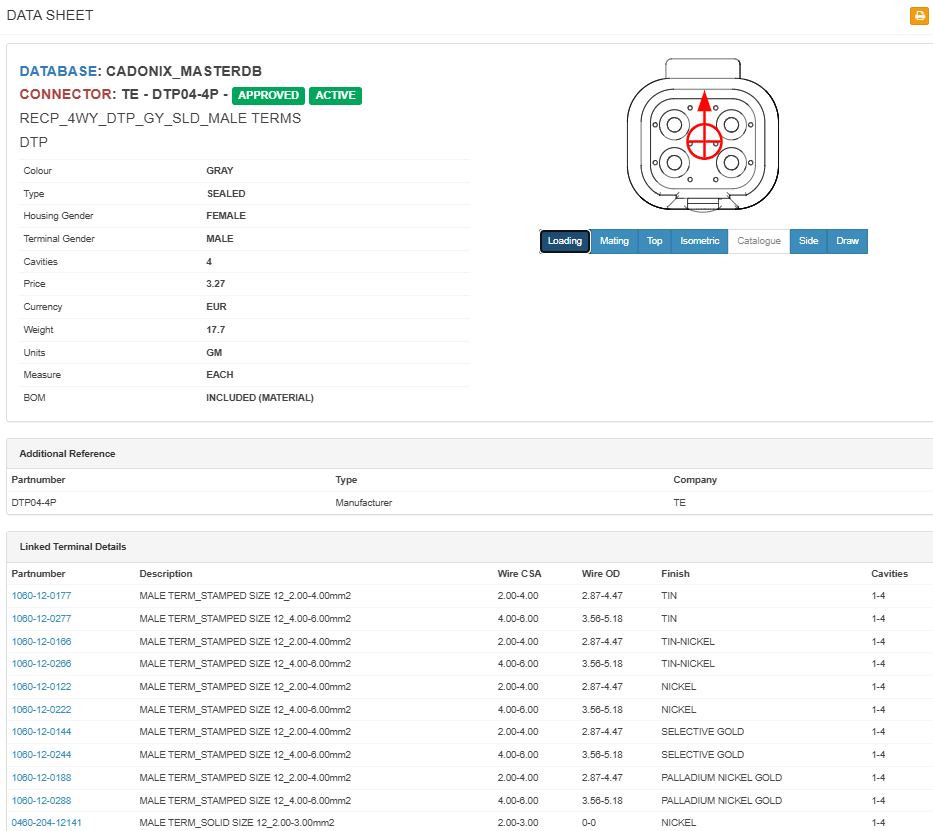

4 – Does your component library provide the parts and components I need?

Unless you plan on manually creating smart components, you’ll want to ask about their library of pre-built components. Understand how many components are available and how much they charge for additional parts if you anticipate needing more. Clarify the product tier you’re evaluating includes the components you discuss if they offer multiple options. During your demonstration or trial, ask how you navigate and search for components when building schematics.

5 – What kind of support do you provide during onboarding and beyond?

Evaluating CAD platforms must consider how quickly you’ll get up and running. Onboarding can vary substantially across companies, so inquire how they handle onboarding and support. Understanding what they include is necessary to evaluate how quickly you’ll be up and running with their solution. Do they provide video tutorials, offer on-site onboarding, or outsource support? Does the software support relevant industry standards like IPC/WHMA-A-620? See if they have a customer you can speak with about their onboarding experience and thoughts about using the platform.

6 – Does the platform run automated design rule checks? If so, how accurate are they?

If you’re evaluating CAD platforms, you will likely need to run automated design checks to ensure your designs are functioning correctly. See what types of automated error checks the solutions run. When asking about this functionality, look for features like double crimps, bundle diameter analysis, and terminal-wire size matching that adhere to IPC 620 standards.

7 – How does the platform send and receive data between schematic designs and manufacturing harness manufacturers?

Unless you’re doing it all in-house, your team probably works primarily on the schematic design or the harness manufacturing side of the process. Regardless, you must understand how the software synchronizes between the schematic and the harness side of the equation. Learn how the platform avoids conflicts between the schematic and harness and maintains a single source of truth.

8 – Can I create Bill of Materials Reports? How detailed are they?

Although more relevant to those involved in harness manufacturing, a crucial report to get right is the Bill of Material (BOM). Ask what’s included in the report, how long it takes to run a report, and request a sample. As a manufacturer, you know the importance of this report, and it’s critical to understand how detailed it is and if it meets your manufacturing needs.

9 – What type of manufacturing documentation can I generate?

Aside from the Bill of Materials, you must also consider other types of manufacturing documentation. Look at the platform’s documentation capabilities, such as assembly instructions, wire lists, test scripts for harness testers, and multicore preparation reports. Also, consider how quickly you receive this documentation and the level of detail provided.

10 – What type of API and integrations do you offer?

When evaluating CAD platforms, you must know which APIs they provide for integration with other tools and if they work seamlessly with ERP/MRP, given your design ecosystem. Either let them know your current tech stack or ask for a comprehensive list of available integrations.

11 – Is anything we discussed an add-on or part of the standard functionality?

A final topic to clarify is whether the above considerations are add-ons or included in the native platform. Ensure the platform tier you purchase has the functionality you require and discussed during your evaluation. The last thing you’d want was to buy a solution that requires unknown costs or add-ons you believed were included in the initial purchase.

Final Thoughts

As you can see, a lot goes into evaluating CAD platforms. The above list is by no means comprehensive, but asking these questions ensures you’ll understand the software’s capabilities and how well it aligns with your wire harness manufacturing needs. Prioritize features that address your most critical design challenges and workflow requirements, which vary based on your workflow.

As you’re evaluating CAD software, consider Arcadia, our end-to-end solution for schematic design, harness manufacturing, and reporting. Engineers are turning to our cloud-based solution to accelerate design times, optimize manufacturing, and reduce scrap, saving hundreds of hours and tens of thousands of dollars. We’re happy to walk you through the platform and offer trials so you can test it out for yourself.